Robotically Controlled Assembly

Leverage your productivity regardless if your products are all identical or completely different. Combining planning data, robotic control and process visualisation, no additional work steps are necessary to move from your shop drawings directly to fabrication.

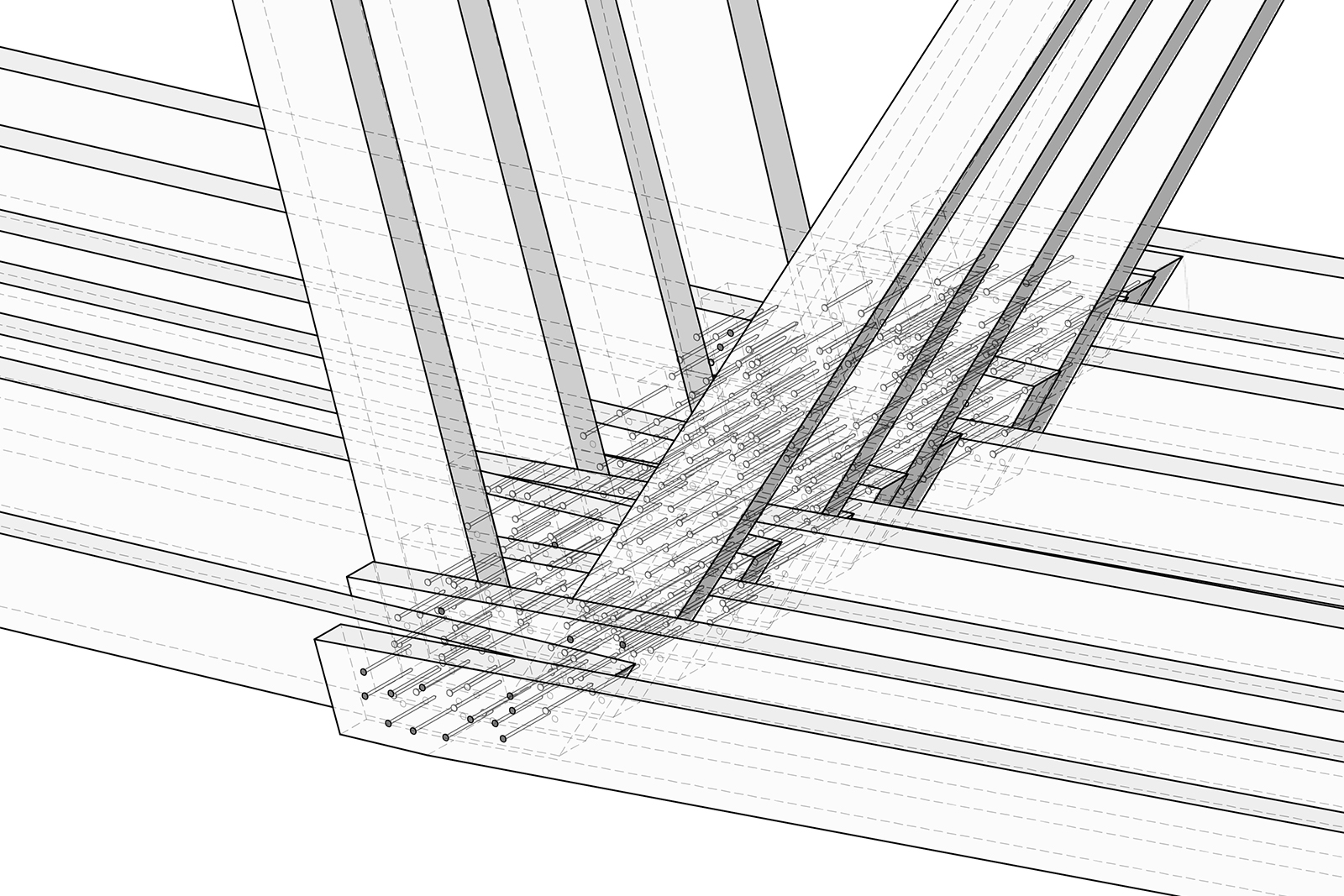

Compared to other sections in the construction industry, the wood industry is already highly advanced in the field of digital fabrication. The unique feature of the WoodFlex robot and its driving software, is the ability to perform unique large scale assembly tasks. Furthermore, the robot is directly driven from BTLx input data, the industry standard CAD interchange format for timber construction, framing and carpentry. The information of the CAD data is automatically translated into handling and processing steps for the robot, rendering any additional work steps obsolete. In this respect, software plays a crucial role in bridging the fabrication gap – an imperative to efficiently produce non-standard elements that otherwise would need to be individually programmed.

Introducing WoodFlex 56

A multi-functional gantry robot specialised on the automated assembly and processing of timber constructions.

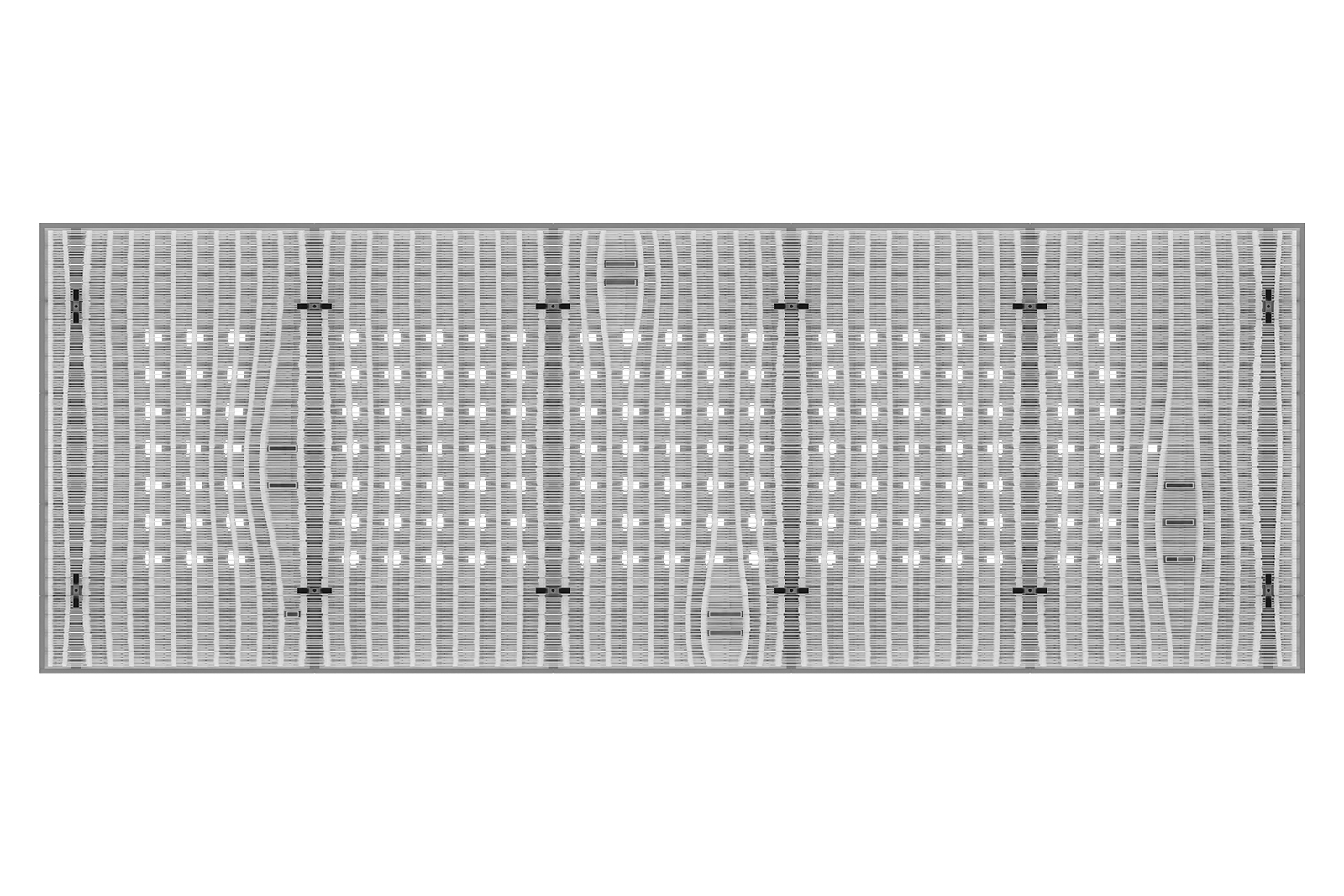

The WoodFlex 56 realised for Erne AG Holzbau in collaboration with Guedel AG features a portal robot equipped with a tool changing system, which allows the robot to perform numerous tasks – from handling large timber boards to shooting nails, cutting and milling. In this project ROB Technology was responsible for developing and implementing the complete control software, featuring an immediate connection between the shop drawings and the robotic control.

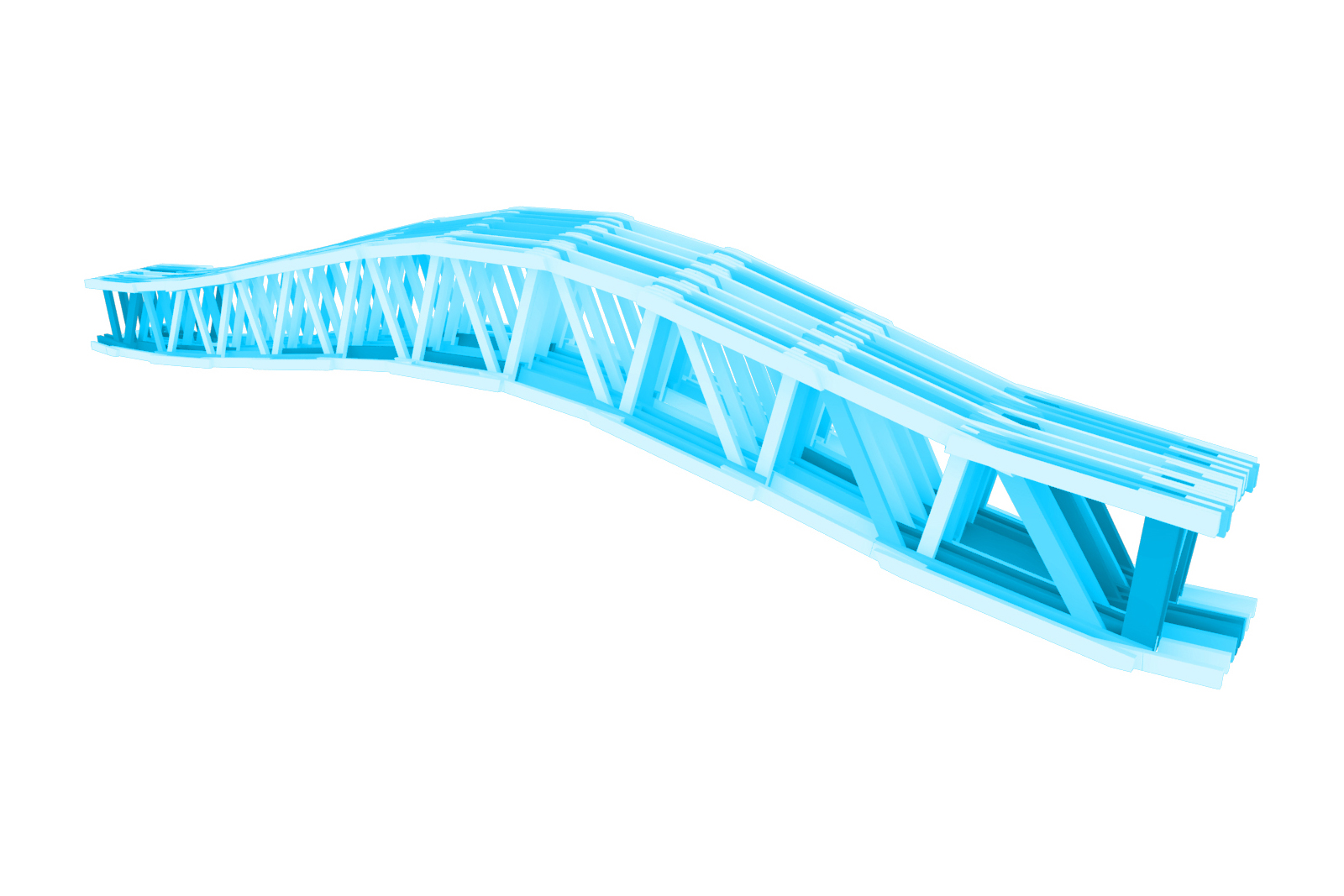

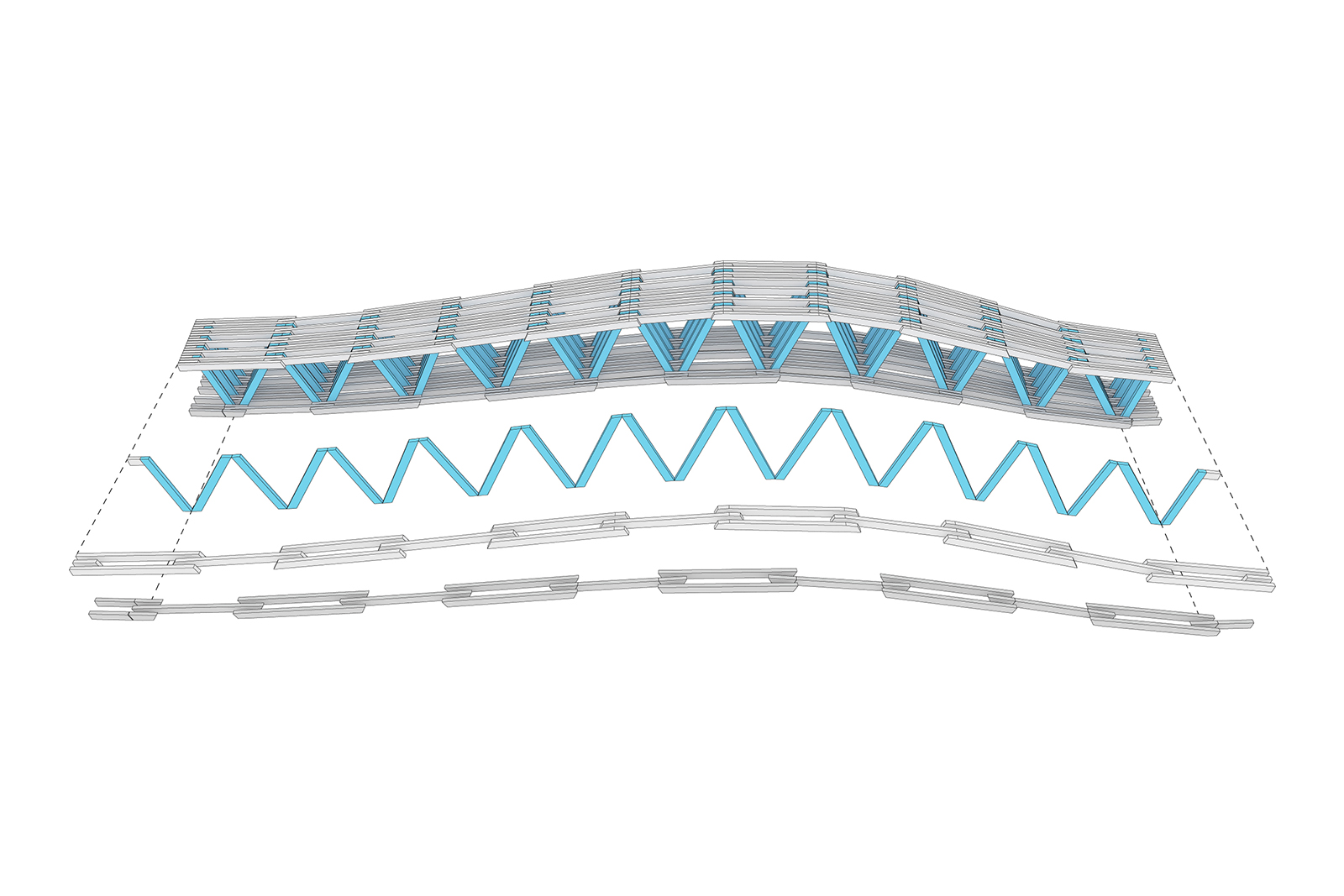

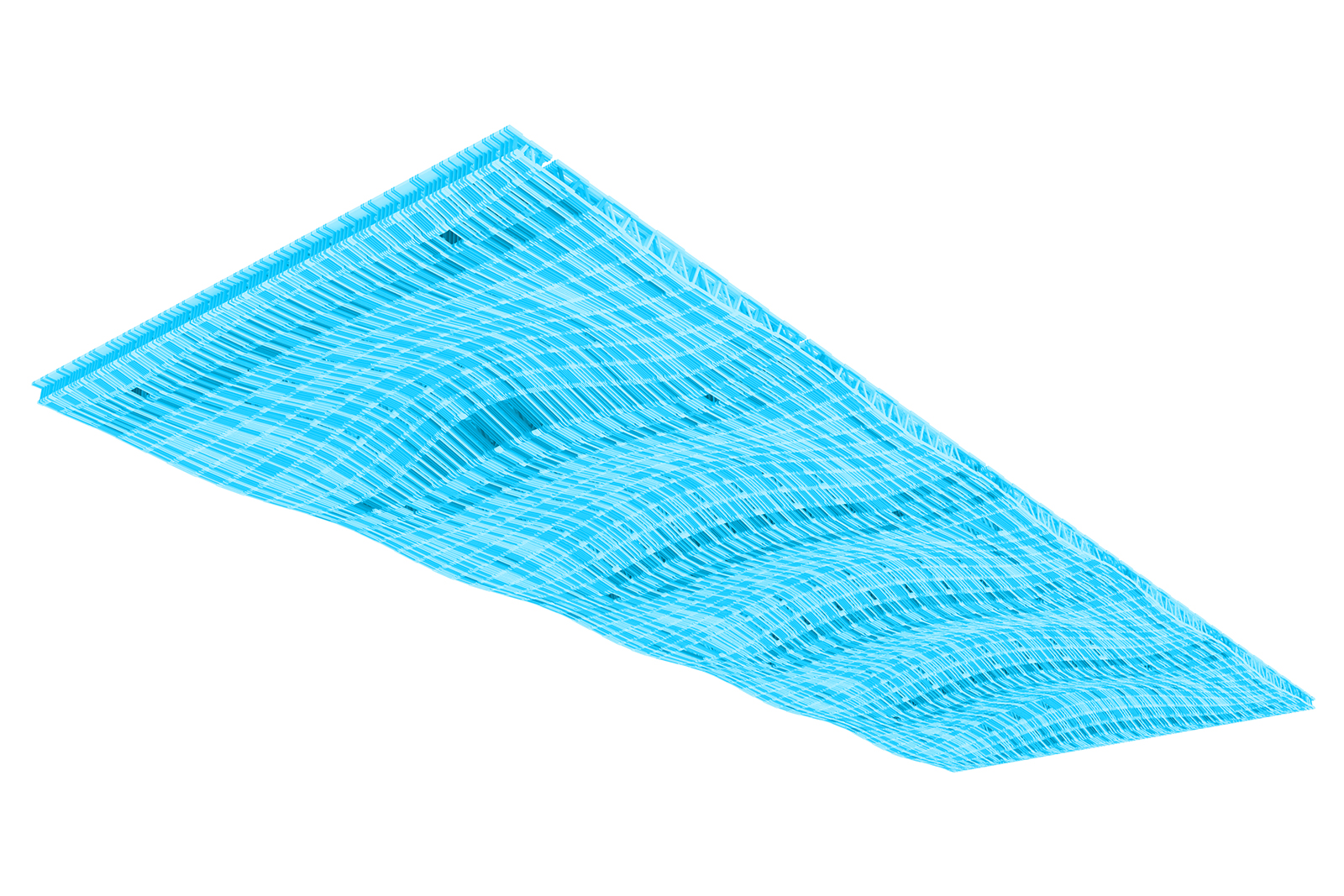

The main field of operation of the WoodFlex 56 is the assembly and processing of individual timber wall modules. However, it is also applied to the fabrication of other non-standard assembly processes, e.g., the fabrication of 168 individual 15-metre-long trusses for a doubly-curved wooden roof structure.

See the WoodFlex 56 in action at Erne AG Holzbau

Non-standard Roof Construction

Interested in Robotic Timber Construction?

Feel free to contact us.

Let us know if we can support you in increasing your productivity through automating your assembly tasks, or you want to be able to offer the fabrication of complex digital designs in timber.